Do you have any questions or would you like a consultation?

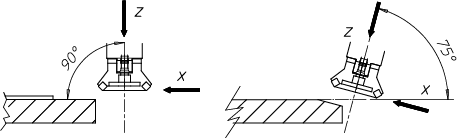

The automatic recess chamfering machine ASO 910 is for welded seam treatment of, for example, duplex steel. The recess chamfering or resetting of cladding is mastered excellently by the edge chamfering machine. The attachment of chamfers on the top edge of the workpiece is possible up to 65mm. Thanks to the gradual angle adjustment from 90° - 75°, clean transitions are created between two workpieces with different thicknesses. The machine is very durable and shows its’ strength in every material through their sturdy construction. Extremely high tool service life can be achieved with the low-speed chamfering. Sheet thickness started at 8mm can be processed. The front, top and/or bottom side can be processed in one step through a special shape chamfer. Cavities in the front can be chamfered using the disc groove cutter.

| Technical data | ASO 910 |

| Motor | 5,5 kW | 0 - 900 rpm |

| Energy | 400 V, 50/60 Hz |

| Maximum feed traverse in X- / Z-axes | 65 mm / 15 mm |

| Angular adjustment | 90° - 75° |

| Workpiece thickness | 8 - 100 mm |

| Weight | 390 kg |

| Item no. | 64247 |