Do you have any questions or would you like a consultation?

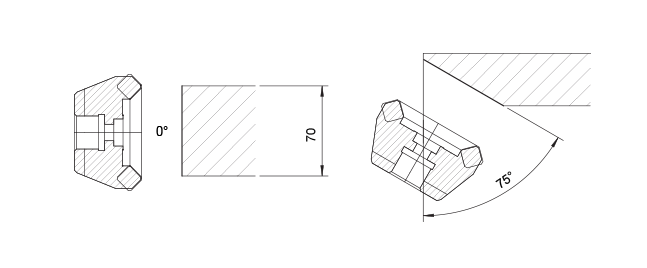

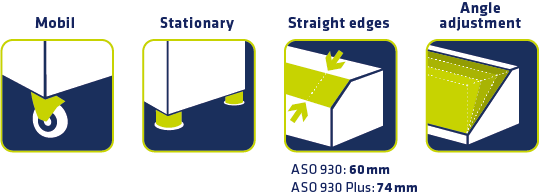

The automatic weld-chamfering machines from the ASO 930 series are for stationary and portable use in weld seam preparation. The attachment of large welded chamfers on the workpiece bottom edge up to a chamfer length of 74 mm can be performed by the machine effortlessly without any thermal change to the material. V, X, K or Y seams can be prepared thanks to the gradual angle adjustment from 0° - 75°. The machines are very durable and show their strength in every material through their sturdy construction. Extremely high tool service life can be achieved with the low-speed chamfering. Sheet thickness started at 8 mm can be processed. Smaller workpieces can be processed manually.

| Technical data | ASO 930 | ASO 930 Plus |

| Motor | 5,5 kW | 800 rpm | 5,5 kW | 0 - 900 rpm |

| Energy | 400 V, 50/60 Hz | 400 V, 50/60 Hz |

| Maximum chamfer width | 59 mm | 74 mm |

| Angular adjustment | 0° - 60° | 0° - 75° |

| Workpiece thickness | 8 - 60 mm | 8 - 70 mm |

| Weight | 205 kg | 380 kg |

| Item No. | 60269 | 67019 |